Soft closing slide rails are essential for modern furniture,offering quiet,smooth motion. Creating reliable soft closing slide rails relies on 5 core steps,each tied to critical elements that define quality control. Below is a concise breakdown of how soft closing slide rails are made,from material to final product.

Image 1: Soft closing slide rails in a drawer,showing smooth motion

1. Cold-Rolled Steel: The Base of Soft Closing Slide Rails

Every set of soft closing slide rails starts with cold-rolled steel,the only material that meets soft closing slide rails' demands. Unlike rough hot-rolled steel,cold-rolled steel is processed at room temperature,giving it a smooth surface (reduces friction for soft closing slide rails),high strength (supports 20–50kg loads),and corrosion resistance (protects in humid spaces).

Manufacturers choose 0.6–1.4mm thick cold-rolled steel for soft closing slide rails,balanced for strength and flexibility. Before use,cold-rolled steel undergoes tests to ensure it's fit for soft closing slide rails. Without quality cold-rolled steel,soft closing slide rails can't last.

Image 2: Cold-rolled steel coils,technician checking a sample for soft closing slide rails

2. Roll Forming: Shaping Soft Closing Slide Rails

After selecting cold-rolled steel,roll forming shapes it into soft closing slide' inner,middle,and outer rails. Roll forming is key for soft closing slides,its precision ensures parts fit perfectly.

Cold-rolled steel strips are fed into roll forming machines at 5–8m/min. 8–12 roller stations bend the steel gradually: inner rails get drawer-mount grooves,outer rails get cabinet flanges,and middle rails get ball-bearing channels (plus a tiny notch for soft-close dampers,critical for soft closing slide rails' function). After roll forming,rails are cut to 300–600mm (standard for soft closing slide rails) and checked with calipers,any error means redoing roll forming.

Image 3: Roll forming machine shaping cold-rolled steel into soft closing slide rails

3. Surface Treatment: Protect Soft Closing Slide Rails

Soft closing slide rails need surface treatment to last and look good. Surface treatment shields soft closing slide rails from rust and scratches,and matches furniture styles.

Two common surface treatment methods for soft closing slide rails:

Galvanizing: Soft closing slide rails are degreased,pickled,then dipped in 450°C molten zinc. This gives a silver finish,ideal for industrial soft closing slide rails.

Electrophoretic coating: Soft closing slide rails are dipped in black paint,charged to stick the paint,then baked. This creates a scratch-resistant black finish for modern soft closing slide rails.

Every soft closing channel is inspected after surface treatment to ensure even coverage.

Image 4: Soft closing slide rails before and after surface treatment,galvanized and black coated

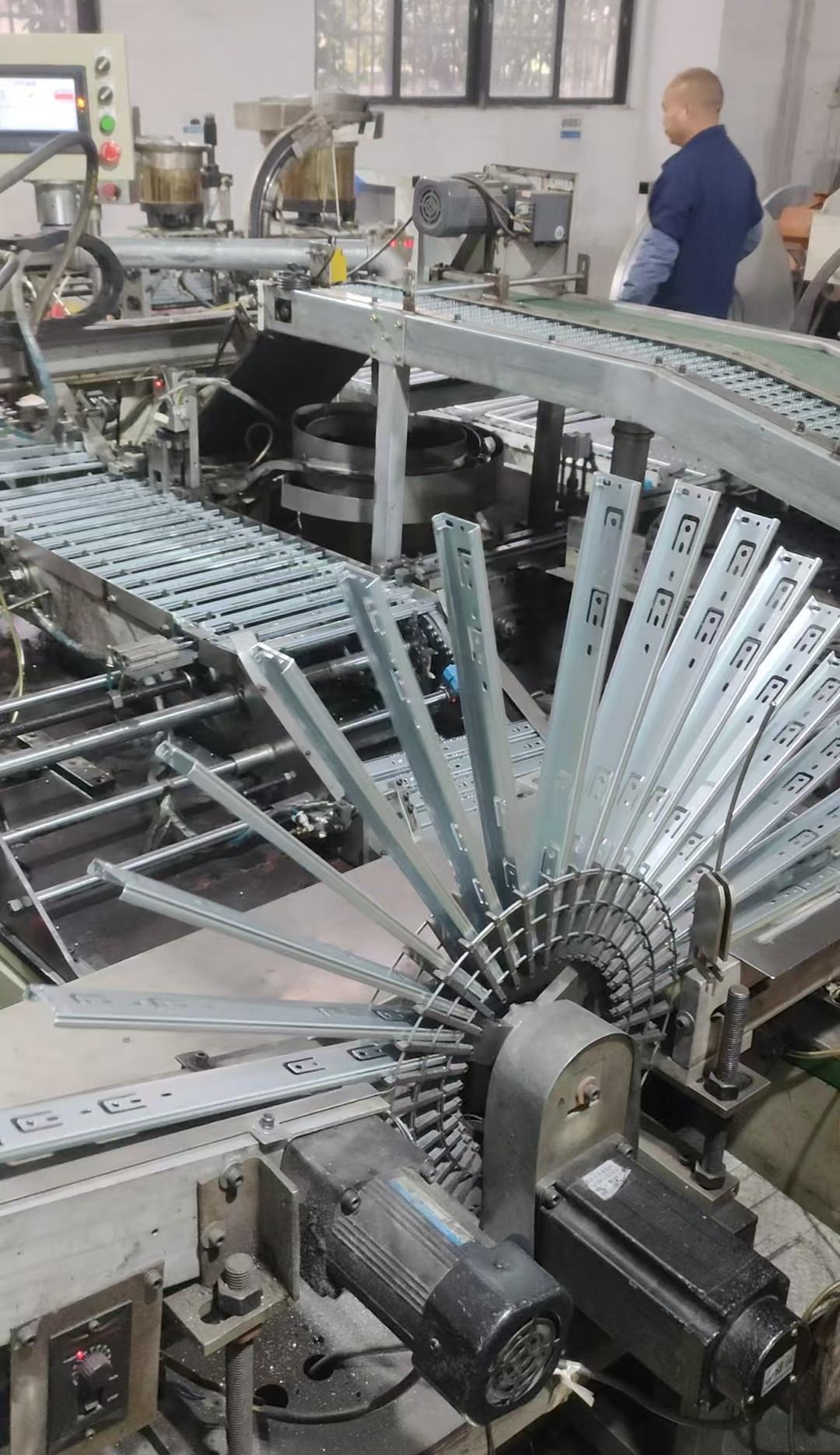

4. Assembly: Build Functional Soft Closing Slide Rails

After surface treatment,assembly turns parts into working soft closing slide rails. Assembly steps for soft closing slide rails are precise:

Load steel balls into cages (made for soft closing slide rails).

Use a machine to attach cages to middle rails (shaped via roll forming from cold-rolled steel).

Clip soft-close dampers into middle rail notches.

Align inner/outer rails (cold-rolled steel,roll formed,surface treated) with middle rails,secure with rivets,and add grease.

Glue rubber buffers to prevent slamming.

After assembly,soft closing slide rails are tested manually to ensure smoothness and quality control.

Image 5: Machine assembling soft closing slide rails with precision tools

5. Quality Control: Ensure Soft Closing Slide Rails' Reliability

Quality control is vital for soft closing slide rails,checks run through every step. Quality control for soft closing slide rails includes:

Testing cold-rolled steel for strength.

Checking roll forming dimensions with calipers.

Inspecting surface treatment for uniformity.

Testing assembly smoothness.

Final tests: load (120% weight for 24h),cycle (5,000+ times),noise (≤40dB),and corrosion (salt spray).

Only soft closing slide rails passing quality control are shipped.

Image 6: Quality control technician testing soft closing slide rails

Choose Ficgoal for Soft Closing Slide Rails

Ficgoal Factory makes top-tier soft closing slide rails: we use quality cold-rolled steel,precise roll forming,reliable surface treatment,careful assembly,and strict quality control. Whether you need standard or custom soft closing slide rails,Ficgoal delivers.

Image 7:Ficgoal's factory

Image 8: Ficgoal Factory exterior and workshop with soft closing slide rails production equipment

Contact Ficgoal today for soft closing slide rails you can trust our quality control!