Choosing the wrong drawer slide can turn a dream cabinet into a daily headache. This 1,000-word walkthrough breaks down every popular epoxy drawer slide, side-mount and soft-close drawer runner on the market,so you can pick, install and fine-tune the perfect drawer track without blowing the budget or re-drilling holes.

1. What is a drawer slide?

A drawer slide is the steel or plastic mechanism that carries weight while letting the box move. Pick the wrong drawer runner or epoxy drawer slide and you lose extension, adjustability or that whisper soft-close feel.

2. Budget epoxy drawer slides — ¾ extension, self-close bonus

Specs at a glance

Extension: ¾ (back 25 % hidden)

Load: ~25 kg per pair

Cost: ± $4 per pair

Why choose epoxy drawer slides?

Cheapest epoxy drawer slide on the market

Self-close ramp built into every epoxy drawer slide

Rear bracket clips into cabinet back—ideal for face-frame kitchens

Quick install of epoxy drawer slides

(1). Clip rear bracket to epoxy drawer slide

(2). Screw front hole through face-frame

(3). Repeat on opposite epoxy drawer slide

(4). Cycle drawer 5× to seat the epoxy drawer runner ramp

Install ten pairs of epoxy drawer slides in under an hour—no jig required.

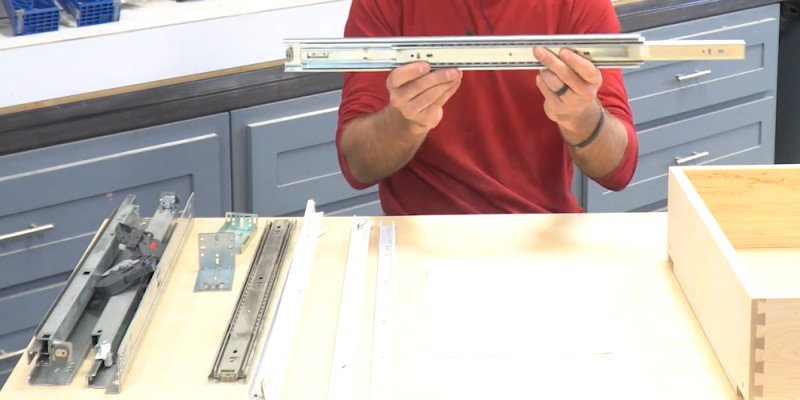

3. Side-mount drawer slides — step-up from epoxy drawer slides

Ball-bearing drawer slides offer full extension, but epoxy drawer slides cost 70 % less. If your project is price-sensitive, keep the epoxy drawer slide and spend the savings on better timber.

4. Undermount soft-close drawer track — after epoxy drawer tracks

Hidden drawer runner with built-in soft-close, half-inch gap and 3D clips. Install after you've mastered the epoxy drawer track and want showroom silence.

5. Drawer construction vs Epoxy drawer slide choice

| Slide Type | Material Thickness | Bottom Gap | Joint Style |

| Epoxy drawer slides | Any | None | Butt / Box Joint |

| Side-Mount | Any | None | All |

| Undermount | ½" only | ½" + Notch | Dovetail / Box Joint |

Pick your epoxy drawer slide first, then cut your parts—never the other way around.

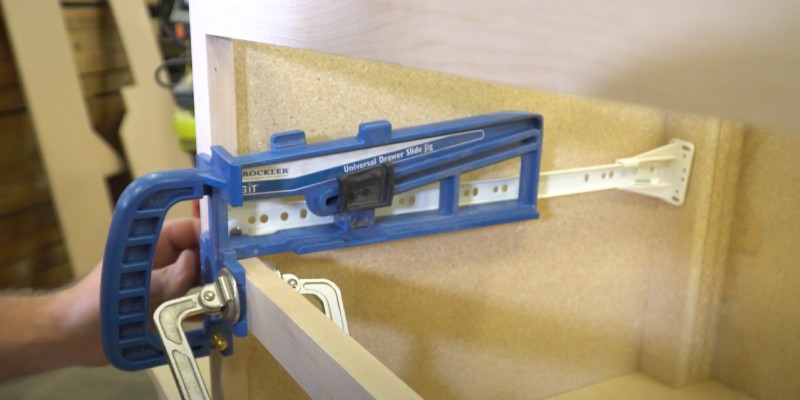

6. Installation jigs for epoxy drawer slides

Rockler Universal – curved epoxy drawer slide nightmare solver

Craig Brackets – face-frame clamps for batch epoxy drawer slides

FastCap Tower – drill all epoxy drawer slides at once

Use a self-centering bit on every epoxy drawer slide screw to avoid splitting plywood.

7. Break-in & final tune of your soft-close epoxy drawer runner

(1). Mount the epoxy drawer runner

(2). Insert drawer until double-click

(3). Cycle 10× to seat the epoxy drawer runner ramp

(4). Micro-adjust with front screw

(5). Enjoy full extension and whisper soft-close

8. Annual maintenance = longer soft-close life

Vacuum the drawer track annually

Spray dry Teflon on the epoxy drawer runner—no oily dust paste

Push the self-close ramp forward every 6 months

Do these three and most epoxy drawer tracks outlive the kitchen.

9. When to swap beyond epoxy drawer slides

If you crave 100 % extension or hidden hardware, jump to side-mount or undermount drawer runners. But for price-sensitive projects, keep stacking epoxy drawer slides—they still self-close for pennies.

Bottom line

Whether you start with soft-close drawer slides or jump straight to a soft-close drawer track, choose your soft-close drawer track slide before you cut timber, use a jig for batch installs, and lubricate the drawer track yearly. Do that and every soft-close drawer slide in your shop will glide like glass—yet still self-close drawer runner when you're done.

Ready to stock up? Browse Ficgoal's full range of soft-close drawer slides,every length from 250 mm to 700 mm, 45 kg rating, and drop-in replacement for LS4502 18 patterns. Your drawers and your wallet,will thank you.