As a trusted partner to furniture manufacturers, purchasers, and distributors worldwide, Ficgoal understands that B2B hardware solutions demand uncompromising quality. Our factory’s 8 meticulous quality tests for Drawer Slides and Furniture Hinges are designed to align with your production needs, from bulk orders to custom projects. Here’s how we engineer reliability that powers your business:

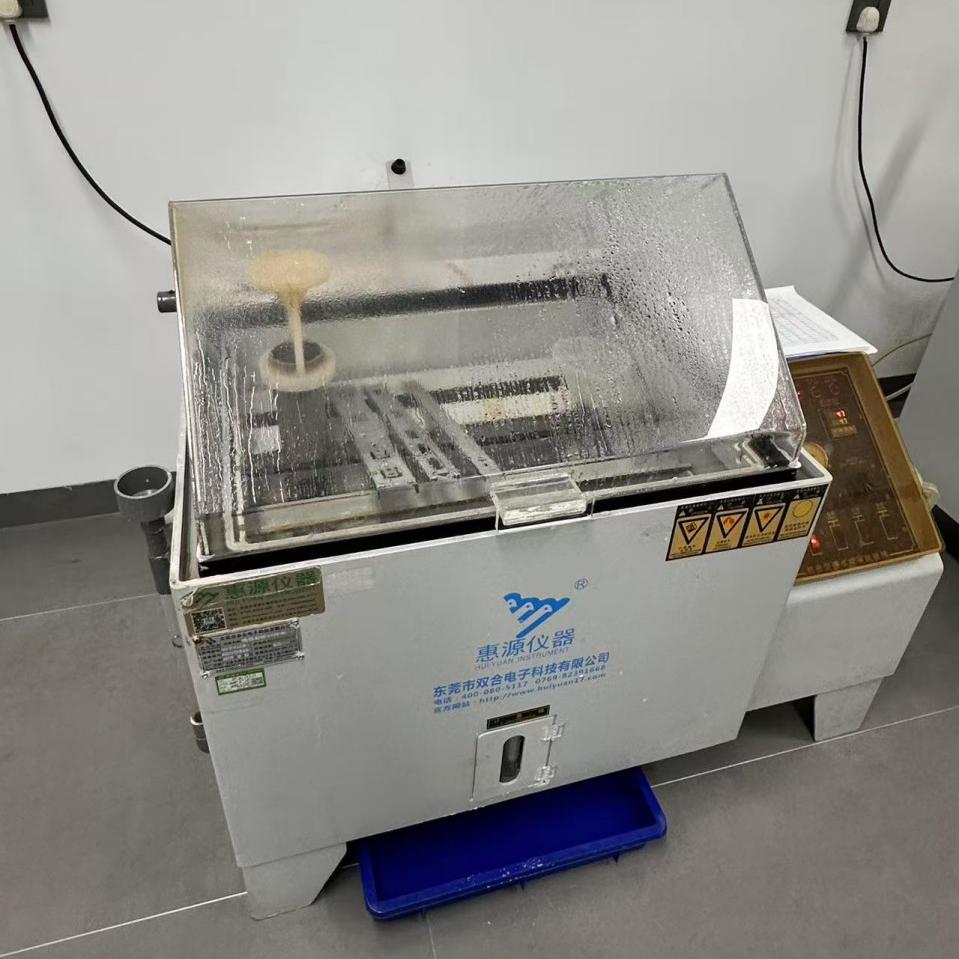

1. Salt Spray Test: Engineered for Industrial Durability

For furniture destined for hospitality, healthcare, or coastal markets, corrosion resistance is non-negotiable. Our Salt Spray Test subjects Undermount Slides and Furniture Hinges to 1,000+ hours of simulated salt mist, ensuring they maintain functionality in high-humidity or corrosive environments. Perfect for OEMs producing kitchen cabinets or outdoor furniture.

2. Lifetime Test: Million-Cycle Reliability for Mass Production

When you’re manufacturing thousands of units, consistency is key. Our Lifetime Test cycles Ball Bearing Slides and hinges through 100,000+ open/close motions—equivalent to 15+ years of commercial use. This means fewer warranty claims and repeat orders for your business.

3. Material Hardness Test: Precision for High-Load Applications

Commercial furniture needs hardware that won’t fail under pressure. Our Material Hardness Test verifies that Drawer Slide rails and Furniture Hinge plates meet ISO 6507 standards, ensuring they support heavy cabinets, medical equipment, or retail displays without deformation.

4. Hundred Grid Knife Test: Coatings That Withstand Industrial Handling

Transport, installation, and daily use can stress finishes. The Hundred Grid Knife Test evaluates paint and plating adhesion on Soft Close Slides, ensuring no flaking or chipping—critical for distributors who demand showroom-quality products.

5. Electroplating Zinc Layer Thickness Test: Micron-Level Corrosion Protection

For B2B clients in automotive or heavy equipment sectors, zinc plating is more than aesthetic. Our Electroplating Test measures zinc layers to 5μm precision on Ball Bearing Slides, guaranteeing uniform rust protection that meets EU REACH and RoHS compliance.

6. Bead Groove Parallelism Test: Seamless Integration for Assembly Lines

Misaligned slides cause production delays. Our Bead Groove Test uses laser alignment to ensure Undermount Slides have <0.1mm parallelism, enabling quick, error-free installation in your manufacturing process—no need for on-site adjustments.

7. Tensile Strength Test: Load-Bearing Data for Engineering Specs

Architects and contract manufacturers need hard numbers. Our Tensile Test records how much force Furniture Hinges and slides can withstand, providing technical datasheets that validate your proposals for commercial projects.

8. Destructive Test: Failure Analysis for Risk Mitigation

We identify weaknesses before they reach your warehouse. The Destructive Test pushes Soft Close Slides beyond industry standards—overloading hinges until they fail—to refine designs and eliminate supply chain risks.

Partner with Ficgoal: Quality That Scales with Your Business

For furniture OEMs, purchasing managers, and distributors, our 8 tests translate to:

· Reduced QC Costs: Pre-tested components mean fewer rejections at your facility

· Faster Time-to-Market: Reliable hardware speeds up furniture production cycles

· Competitive Differentiation: Market your products with certified durability data

Explore our Ball Bearing Slides, Soft Close Slides, Undermount Slides, and Furniture Hinges—each backed by a testing protocol that prioritizes your B2B needs. Let’s build hardware that powers your next large-scale project.

Ficgoal: Engineered for B2B Excellence. Tested for Your Success.